- SAE/BOSS

| SAE/BOSS Thread Specifications | |||

|---|---|---|---|

| Thread Size | Nominal Size (in) |

Number of Threads per Inch | Male Thread O.D. (in) |

| 2 | 1/8 | 24 | 5/16 |

| 3 | 3/16 | 24 | 3/8 |

| 4 | 1/4 | 20 | 7/16 |

| 5 | 5/16 | 20 | 1/2 |

| 6 | 3/8 | 18 | 9/16 |

| 8 | 1/2 | 16 | 3/4 |

| 10 | 5/8 | 14 | 7/8 |

| 12 | 3/4 | 12 | 1-1/16 |

| 14 | 7/8 | 12 | 1-3/16 |

| 16 | 1 | 12 | 1-5/16 |

| 20 | 1-1/4 | 12 | 1-5/8 |

| 24 | 1-1/2 | 12 | 1-7/8 |

| 32 | 2 | 12 | 2-1/2 |

|

|

|

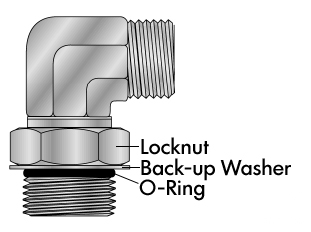

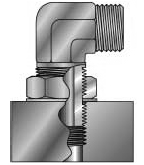

Fig. 3 Adjustable Port End Assembly

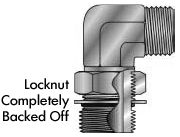

Step 4

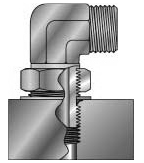

Step 5

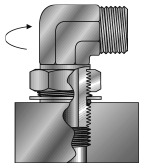

Step 6

Step 7 & 8 |

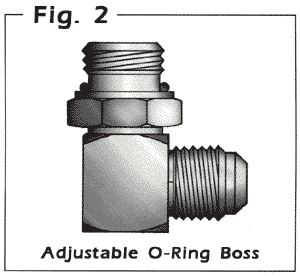

- Inspect components to ensure that male and female port threads and sealing surfaces are free of burrs, nicks, and scratches, or any foreign material.

- If o-ring or seal is not pre-installed to fitting male port end, install proper size o-ring or seal, taking care not to damage it.

- Lubricate o-ring with light coating of system fluid or a compatible lubricant to help the o-ring slide past the port entrance corner and avoid damaging it.